Business Department

MATRIX LIGHT believes all the business relationship must be connected by mutual support. With new equipment, latest technology and advance research team, MATRIX LIGHT will earn the long term business relationship with customers.

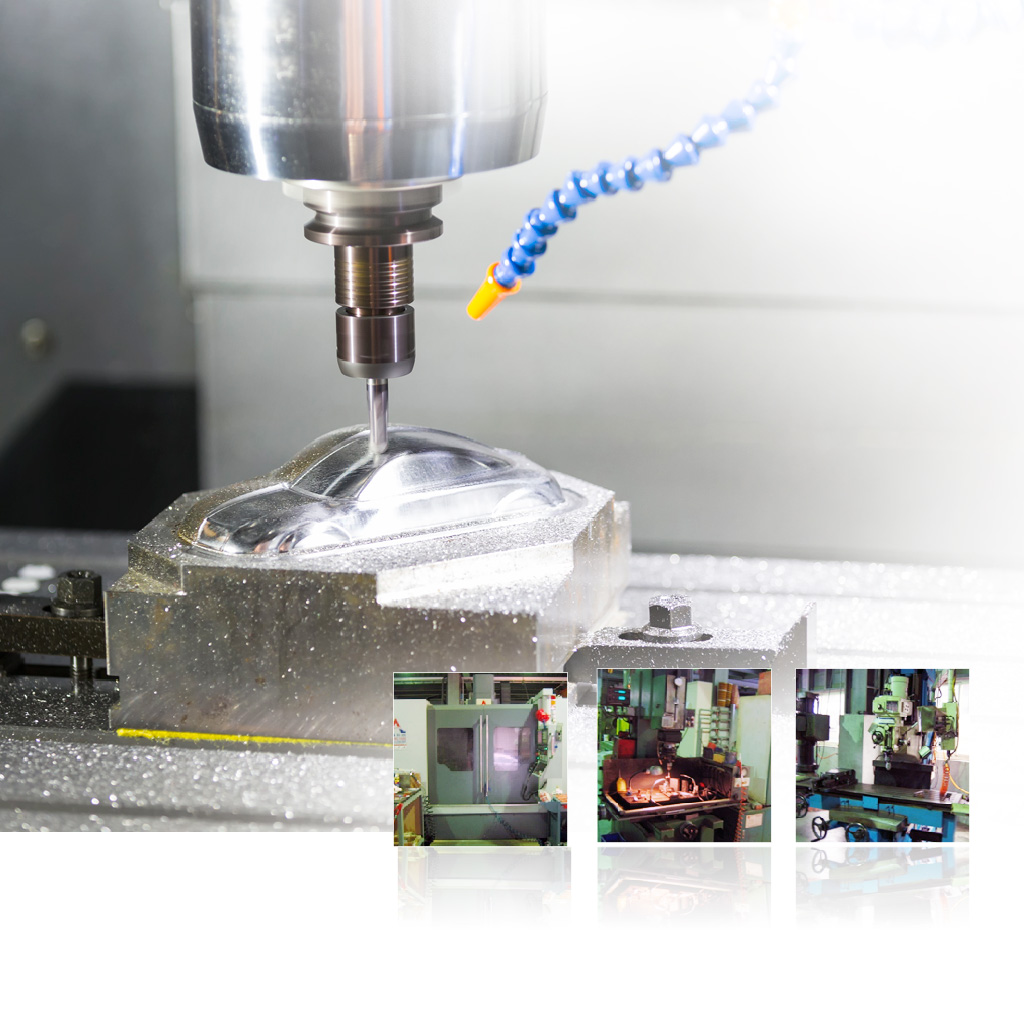

The company has a professional mold manufacturing plant equipped with high-precision mold production equipment to achieve the perfect combination of technology and manufacturing processes.

MATRIX LIGHT believes all the business relationship must be connected by mutual support. With new equipment, latest technology and advance research team, MATRIX LIGHT will earn the long term business relationship with customers.

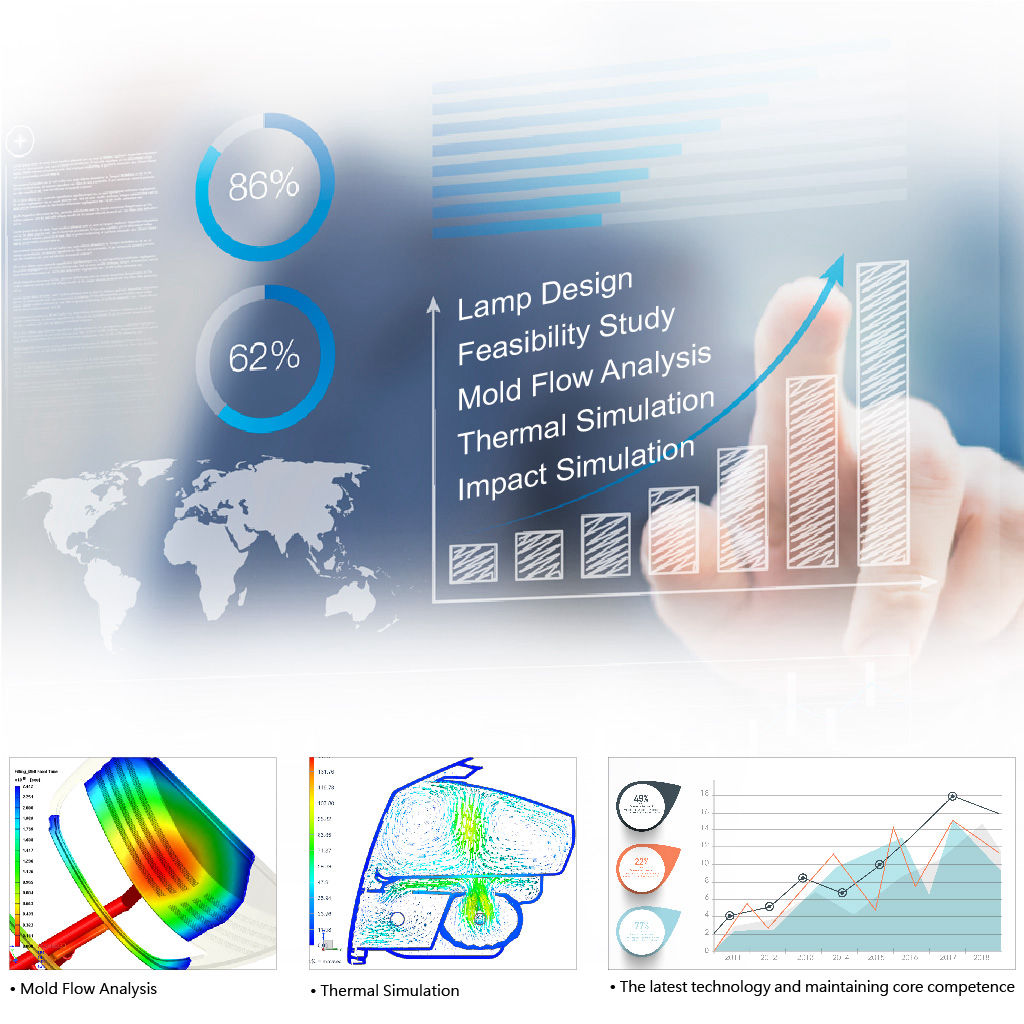

MATRIX LIGHT always keep studying the latest technology and maintaining core competence. Not only develop multiple applications for lamp industry but also increasing company and customer corporate image.

• Lamp Design(Optical and Circuit Design)

• Feasibility Study

• Mold Flow Analysis

• Thermal Simulation

• Impact Simulation

MATRIX LIGHT has molds making department and equipped high precision CNC and EDM machines. Mold technicians have 25 years experiences which can always accomplish customer’s request on time.

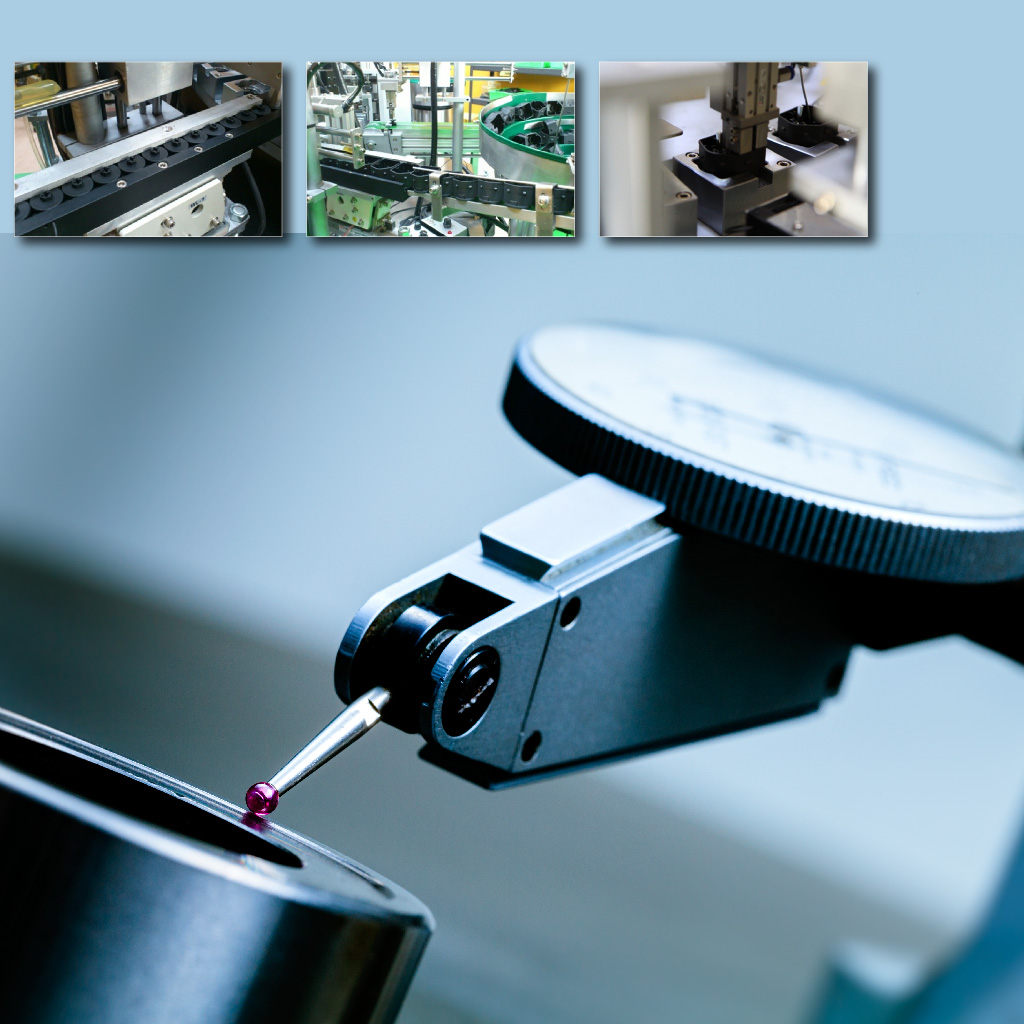

MATRIX LIGHT’s injection department had built complete production history forms for quality assurance. All the plastic parts have checked by operator person to make sure there is no defective part and provide the best quality products to customers.

MATRIX LIGHT has modern assembling equipment and automatic assembling machine to not only avoid man power errors but also increase the production efficient. Before delivery to our customers, all our products need to go through assemble and test then pack and check procedure to control the quality.

Quality Control, Quality Check, System Documents and Procedure management are four principles of MATRIX LIGHT quality policy.

• Daily produce report

• Vibration Test

• 100% Functional Test

• Leakage Test

• Noise Test